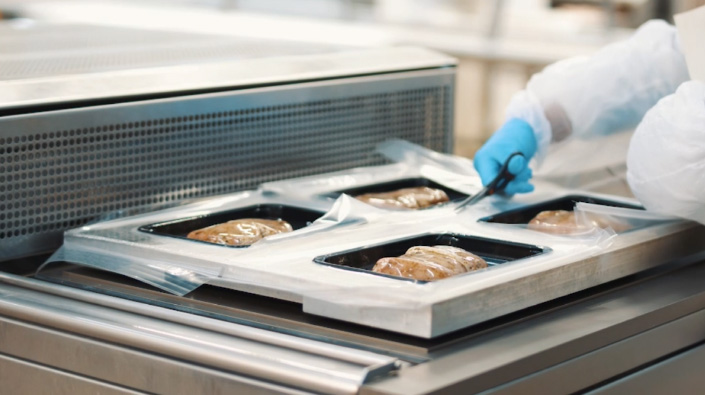

Sealed Packaging Inspection Systems in the Food Industry

18 - 09 - 2024

In the food industry, the quality of sealed packaging is essential to ensure product safety and preservation. Sealed packaging inspection systems play a crucial role in preventing defects that could compromise the freshness and safety of the food. A defective seal not only risks the product’s quality but also food safety, as it may allow contaminants to enter or the package’s integrity to be compromised.

These systems detect a wide range of defects, such as deformations, bubbles in the seal, misaligned packaging, or incorrect or incomplete barcodes. Through automation and advanced technologies like artificial intelligence (AI), precise and efficient real-time control is possible, even on high-speed production lines.

The importance of inspection in the food industry cannot be overstated. Consumers trust that the products they buy are not only safe for consumption but also delivered in optimal conditions. Regular inspection of sealed packaging ensures that there are no leaks or deterioration, guaranteeing that the food retains its properties throughout its shelf life.

Recommendation: AIS KARIKÓ Inspection System

For companies looking to improve the quality of their sealing control, the AIS KARIKÓ Sealing Control System is a highly efficient and adaptable solution for different types of products and packaging. This system uses high-resolution cameras and AI algorithms to detect defects in real-time, ensuring that each package meets the highest quality standards.

If you are interested in implementing this innovative solution in your production line, visit our website for more information: AIS KARIKÓ Sealing Control System.