Sealing Control System: AIS KARIKÓ

16 - 09 - 2024

In modern production lines, the quality of sealing is essential to ensure the safety and presentation of products. AIS KARIKÓ is an advanced inspection system specifically designed to detect sealing defects, ensuring that every package meets the highest quality standards. This system is ideal for industries such as food, pharmaceuticals, and cosmetics.

What is AIS KARIKÓ?

AIS KARIKÓ is a sealing inspection system that uses high-resolution cameras and artificial intelligence (AI) algorithms to detect defects such as deformations, bubbles in the seal, incorrect or partial barcodes, among others. Thanks to its ability to adapt to high-speed production lines, it allows precise real-time controls.

Contact us for more information

Key Features of AIS KARIKÓ:

- Precise sealing detection: Able to identify deformations, bubbles, and other common defects in the sealing of containers.

- High speed: Processes images at high speeds, making it ideal for high-volume production lines.

- Versatility: Adaptable to different types of production lines, even in limited spaces.

- Comprehensive control: Verifies the status of the seal, the presence of barcodes, and other key quality control elements.

- Efficient automation: Includes an automatic rejection system that separates defective products, minimizing losses in the production line.

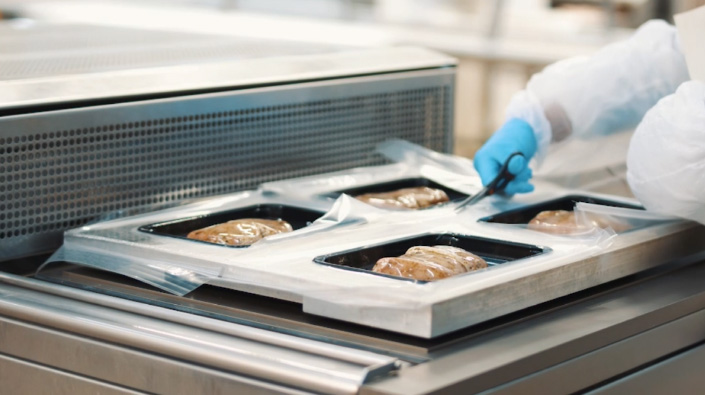

AIS KARIKÓ sealing control system ensures flawless seals in the food industry.

Benefits of AIS KARIKÓ for Your Production

The AIS KARIKÓ Sealing Control System from AIS Vision Systems is a complete solution to ensure quality on production lines that require perfect sealing. Not only can it adapt to a variety of products and containers, but its Rosepetal AI platform allows for easy customization and the creation of new formats.

Thanks to its compact design and ability to handle products of different sizes and formats, AIS KARIKÓ ensures high-quality sealing on every package.

Applications in Different Industries

- Food: Inspection of seals on products such as pizzas, tortillas, meats, etc.

- Pharmaceutical: Quality control of seals on vials and medical products.

- Cosmetics: Inspection of seals on cosmetic product containers.

AIS KARIKÓ is an essential tool for companies looking to improve their quality control in sealed products, increasing efficiency and reducing the risk of defective products.

Why Choose AIS KARIKÓ?

AIS KARIKÓ offers a comprehensive solution to ensure sealing quality in any production line. Its compact design, ease of use, and precise detection capabilities make it an essential tool for companies that want to ensure excellence in every product.

Below, we show AIS KARIKÓ in action, inspecting seals on a production line:

If you’re looking for an adaptable and efficient solution to improve sealing quality on your production line, don’t hesitate to contact us for more information about AIS KARIKÓ.