What does the inline OMRON V275 verification system have to offer?

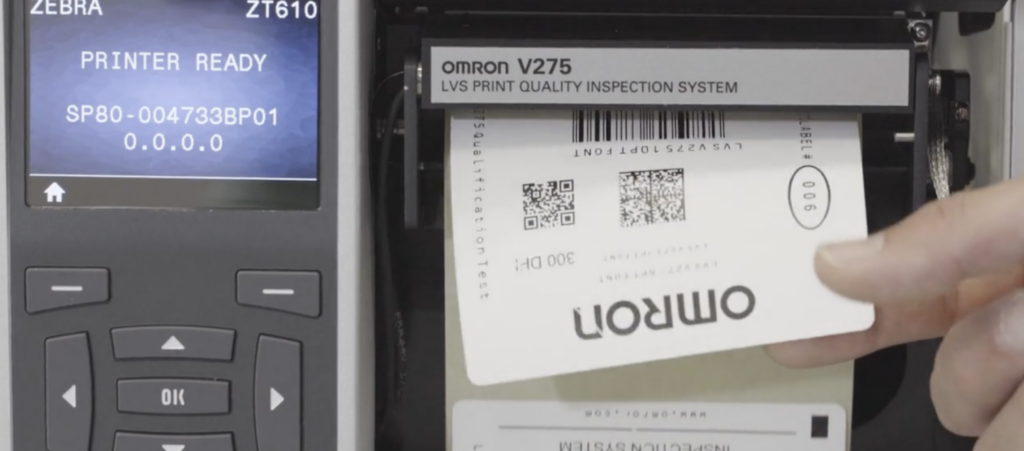

AIS Vision Systems is the exclusive distributor in Spain of the inline verification systems developed by Omron LVS (Label Vision Systems). These systems are compatible with industrial desktop printers, label applicators, and industrial flexographic, offset, or digital label printers.

This is everything AIS Vision Systems offers in the field of inline verification:

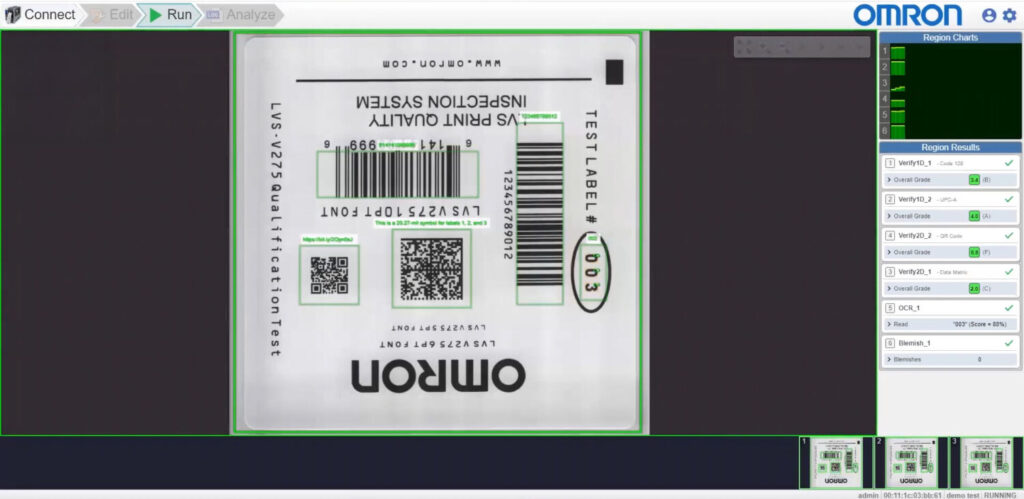

- Quality control that meets GS1 barcode quality requirements, ISO standards, FDA regulations, UDI, FMD, the French CIP, and other relevant standards and organizations.

- Simple verification of both printed labels and DPM (Direct Part Marking) codes created by laser, etching, or micro-puncture.

- Verification of multiple label features beyond the barcode itself, including text analysis and detection of imperfections.

- Validation of the content of each label field and print quality, minimizing errors, incidents, or customer returns.

- Comprehensive analysis of marking quality with the generation of detailed reports and integration with external database communication systems.

- Ability to adjust illumination based on the material or surface where the direct marking has been applied.