Managing print production: how to avoid printing errors?

02 - 03 - 2023

If you have a print shop or if your supplier is a printer, it is necessary to follow a process to verify the product that reaches the end customer meets the quality standards. During the management of print runs, we can automate the quality controls so that the final result is optimal.

What is printed design control?

It is a critical step in the graphic design and production process. It ensures that all materials produced and files created for a project are accurate and meet industry standards and client requirements.

Both content and printing can be checked.

We can carry out this control automatically with the help of artificial vision systems. In this way, human resources can be optimised and any type of error can be avoided when validating the final artwork, before the entire print run or during final production.

What parameters can we control?

During any of the steps of print production, you can validate:

- Colour accuracy

- That there are no textual errors or spelling mistakes

- That the font families are correct

- Possible differences between what is being printed and a validated pattern

- That all elements of the design come together correctly

- Braille texts

- Data such as barcodes, batches or expiration dates

- ISO verification of the quality of printed barcodes and Data Matrix

During print production, it also checks for any potential problems that may arise during printing or production. These can include defects in the substrate as well as errors in codes or data.

The control of package printing

Quality control is not just limited to 2D printed designs, such as instruction manuals, corporate brochures, etc.

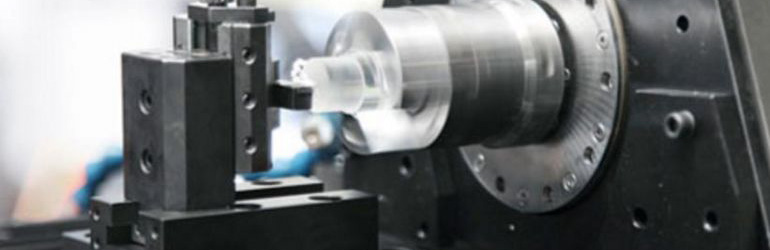

It is also good to automate the control of the package printing, whether it is packaging that would be flat (2D) when unfolded, such as cylindrical containers.

Variable print control

In some cases, variable print control is necessary. For example, in the printing of numerical sequences (batch numbers, expiration dates, serial numbers and Data Matrix codes, 1D codes, among others).

A correct quality control of the graphic arts makes it possible to validate that this type of printing is also carried out correctly.

How to automate the management of print production?

Using a graphical inspection platform controlled by artificial vision. Software of this type is key to automating the management of print production.

You will be able to have reports on the status of your prints so you can always keep track of what is being printed.

In the case of variable printing, we can implement traditional machine vision systems or deep learning, which is a high-precision data extraction and processing technique based on neural networks.

Quality control in the different stages of print production

From AIS Vision, we offer you online and also offline systems, thanks to the Global Vision system. We can help you from the pre-printing process (pre-printing) to the final printing, including the sample printing stage.

Are you a print shop looking to improve graphic art quality controls? Does your product require printed material and you want to make sure it always looks perfect? During production in graphic arts industries, it is essential to have everything under control.

Contact us and we will give you the best advice on the most suitable solution for your company.