360 Cap Control System: AIS Hopper

14 - 09 - 2024

360 Cap Control System: AIS Hopper

In today’s production lines, the quality of capping is essential to ensure the longevity and safety of products. The AIS Hopper is an innovative 360º cap control system that guarantees a complete inspection of caps, ensuring that each bottle or container is properly sealed. This system is ideal for industries such as food, beverages, chemicals, and pharmaceuticals.

What is the AIS Hopper?

The AIS Hopper is an advanced cap inspection system that uses high-resolution cameras to perform a full 360-degree control. This system detects various defects in capping, including the presence of a solidary cap, batch marking, and incorrect cap positioning. Additionally, it can operate at speeds of up to 5 units per second, making it an ideal solution for high-speed production lines.

Contact us for more information.

Key Features of the AIS Hopper:

- 360º Inspection: Provides complete control of the cap and handle on each container, ensuring no defects in the capping process.

- High Speed: With a processing capacity of up to 5 products per second, the AIS Hopper is perfect for intensive production lines.

- Versatile Design: Adaptable to all types of production lines, including those with space limitations thanks to its compact design and rotating arm.

- Comprehensive Control: Verifies product level, the presence of labels and markings, as well as the correct position and quality of the cap.

- Efficient Automation: The system offers automatic rejection of defective products and stores images for future analysis.

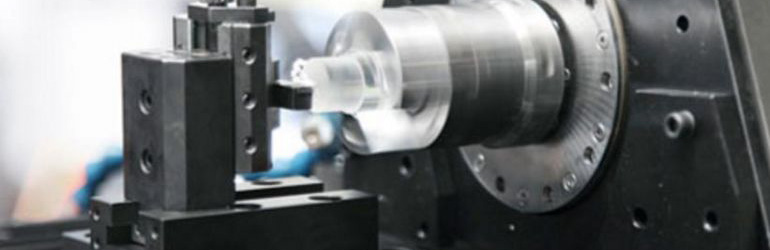

Below, we show the AIS Hopper system in action, performing a 360º Cap Inspection on a production line:

Benefits of the AIS Hopper for Your Production

The 360 Cap Control System by AIS Vision Systems is a comprehensive solution to ensure quality in all production lines.

The AIS Hopper not only adapts to different types of containers, including plastic, glass, and metal bottles, but it also allows customization of rejection settings to meet the specific requirements of each product. Thanks to its automatic height adjustment, the system can accommodate a variety of product sizes and formats without the need for manual adjustments.

Additionally, the AIS Hopper’s intuitive software makes it easy to create new formats and ensures that the system is user-friendly, even for operators with little experience.

Learn more about Artificial Vision.

Applications in Different Industries

With the 360 Cap Control System, every container is inspected from all angles, ensuring that the capping meets the highest quality standards.

The AIS Hopper system inspects cap defects, batch marking, handles, and fill levels in containers.

The AIS Hopper is a perfect solution for industries that require rigorous quality control in capping, such as:

- Food Industry: Wines, sparkling wines, oils, water, and soft drinks.

- Pharmaceuticals: Inspection of vials and chemical products.

- Cleaning Products: Soaps and detergents with special containers.

Thanks to its robustness and versatility, the AIS Hopper can ensure that every container meets the highest quality standards, improving the efficiency of your production line and reducing the risk of defective products.

Why Choose the AIS Hopper?

The AIS Hopper 360º Cap Control System offers a comprehensive solution to guarantee capping quality on any production line. Its compact design, ease of use, and precise inspection capabilities make it an indispensable tool for companies looking to ensure excellence in every product.

If you’re looking for an efficient and adaptable solution to improve the capping quality on your production line, contact us here for more information about the AIS Hopper.