Label Inspector in the Production Line: Ensuring Product Quality

21 - 10 - 2024

In industries such as food, beverage, pharmaceutical, and cosmetics, proper labeling is crucial for ensuring the correct presentation of the product and regulatory compliance. This is where an automated label inspector comes into play, ensuring that each product meets quality standards before reaching the consumer.

Defective labeling can cause significant problems, such as product recalls, fines, or loss of customer trust. Therefore, advanced label inspection systems are essential for detecting errors such as defective barcodes, illegible expiration dates, or misaligned labels.

Benefits of a Label Inspector in Production

Label inspection systems offer numerous advantages for companies seeking to optimize quality control. Here are some key benefits:

- Complete Product Coverage

An advanced label inspector ensures thorough inspection of each label, identifying defects such as bubbles, creases, and printing or adhesion issues, making sure the product leaves in perfect condition. - Adaptability to Different Containers

Inspection systems easily adapt to a variety of shapes and sizes, from bottles and boxes to tubes, ensuring consistent and accurate inspection across the entire production line. - High Speed without Compromising Quality

Modern label inspectors operate at high speeds, which is essential for maintaining a high production pace without sacrificing labeling precision. - Reduction of Waste

By detecting and removing defective products before reaching the market, costs associated with rework and product recalls are reduced, minimizing environmental impact as well. - Guaranteed Regulatory Compliance

Complying with regulations is essential to avoid penalties and ensure that products can be marketed in various regions. An automated inspection system ensures that each product meets local and international standards. Check out the labeling regulations in the European Union here for more information on specific requirements in the beverage industry.

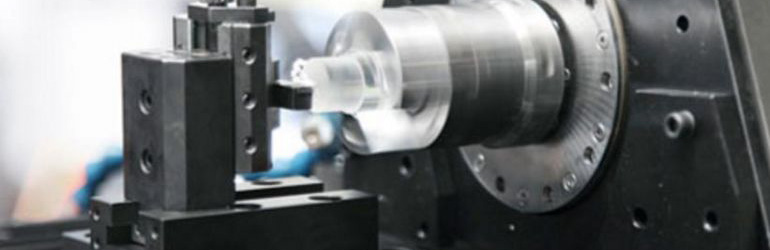

AIS REV 360 Label Inspector for Optimal Control

To achieve reliable and comprehensive label inspection, the AIS REV 360 from AIS Vision Systems is the ideal solution. This 360-degree inspection system uses advanced vision technology and deep learning algorithms to detect defects in real time, ensuring each container meets the highest quality standards. With the ability to adapt to different types of containers and operate at high speeds, the AIS REV 360 guarantees precise inspection across the production line.

Discover how the AIS REV 360 can optimize your production line and ensure the highest quality.