Label Inspection System: The Key to Quality Control in Production

24 - 10 - 2024

In today’s industry, ensuring precise and high-quality labeling is essential for product presentation and regulatory compliance. An automated label inspection system allows companies to verify each label meticulously, reducing risks and increasing efficiency.

What is a Label Inspection System?

A label inspection system is an automated solution that uses artificial vision technology to detect label defects, such as misalignment, damage, bubbles, or errors in printed information. These technologies have become essential for industries that rely on accurate labeling, including food, pharmaceutical, and cosmetic sectors.

Benefits of a Label Inspection System

- Quality Assurance:

Automated inspection ensures that all labels are accurately checked, identifying any defects before products reach the market. - Regulatory Compliance:

Meeting regulatory standards is crucial for avoiding penalties and ensuring products can be exported to various markets. A label inspection system helps comply with local and international standards. - Waste Reduction:

Detecting defective products before they leave the production line minimizes waste and the costs associated with rework or product recalls. - Production Process Optimization:

Integrating the label inspection system into the production line optimizes workflow and improves operational efficiency, allowing high volumes to be achieved without compromising quality.

Use Cases for the Label Inspection System

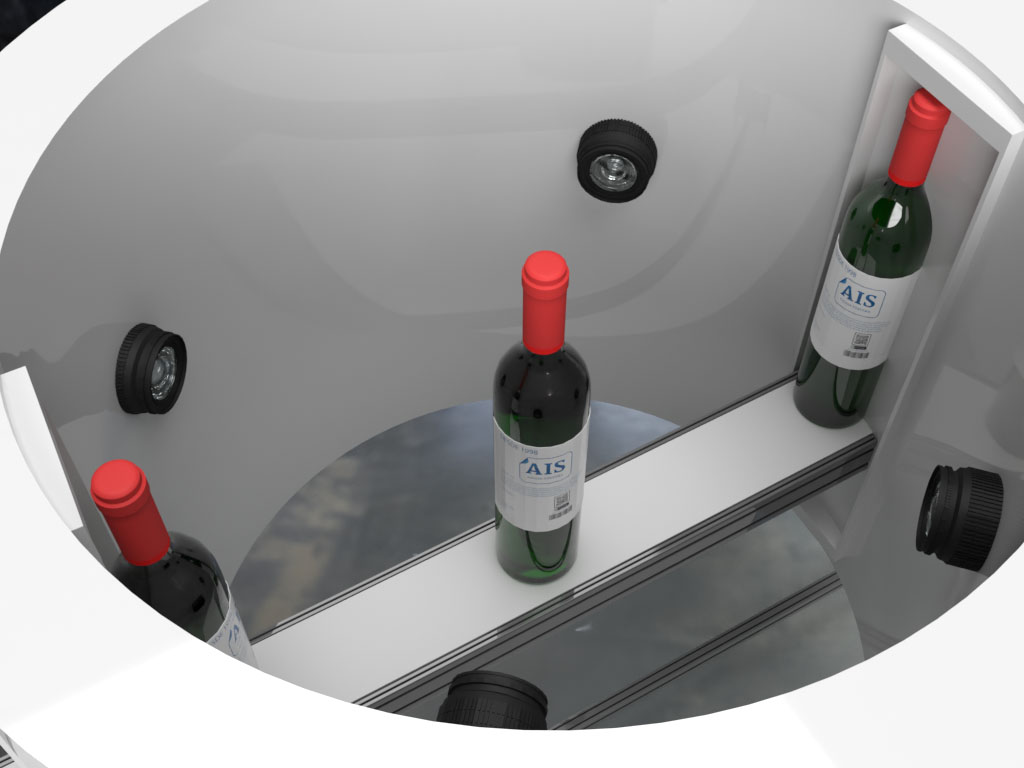

- Beverage Industry:

Ensures labels on bottles and cans are properly placed and legible, meeting safety and presentation standards. - Pharmaceutical Sector:

Verifies that medication labels contain accurate and legible information, preventing health risks for consumers. - Food and Cosmetics:

Detects misaligned, improperly attached, or incomplete labels, enhancing product presentation.

Artificial Vision and Artificial Intelligence (AI) Technology

Modern inspection systems, such as the AIS REV 360, use high-resolution cameras and AI algorithms to detect even the smallest defects in real-time. This allows for immediate adjustments on the production line and ensures that each product meets the highest quality standards.

Why Choose a Label Inspection System from AIS Vision Systems?

At AIS Vision Systems, we offer customized solutions tailored to the specific needs of each client. Our label inspection system uses the latest artificial vision technology to ensure precise and effective inspection, optimizing both quality control and production efficiency.