Tube Quality Control: How to Guarantee a Defect-Free Production

26 - 06 - 2025

In modern industry, tubes are used across a wide range of critical applications: from fluid transport in industrial plants to medical components, metal structures, or hydraulic systems. Any manufacturing defect can lead to serious consequences. That’s why implementing an efficient tube quality control system has become essential to ensure product safety, durability, and performance.

What Does Tube Quality Control Involve?

Tube quality control consists of continuously inspecting their physical and geometric properties during production. Key aspects include:

- External and internal diameter

- Wall thickness

- Straightness

- Ovality

- Presence of cracks, dents, or impacts

- Surface defects like scratches or impurities

Traditionally, many of these inspections were done manually, increasing the risk of human error, rework, and additional costs. This is why automated inspection technologies like machine vision have become key solutions.

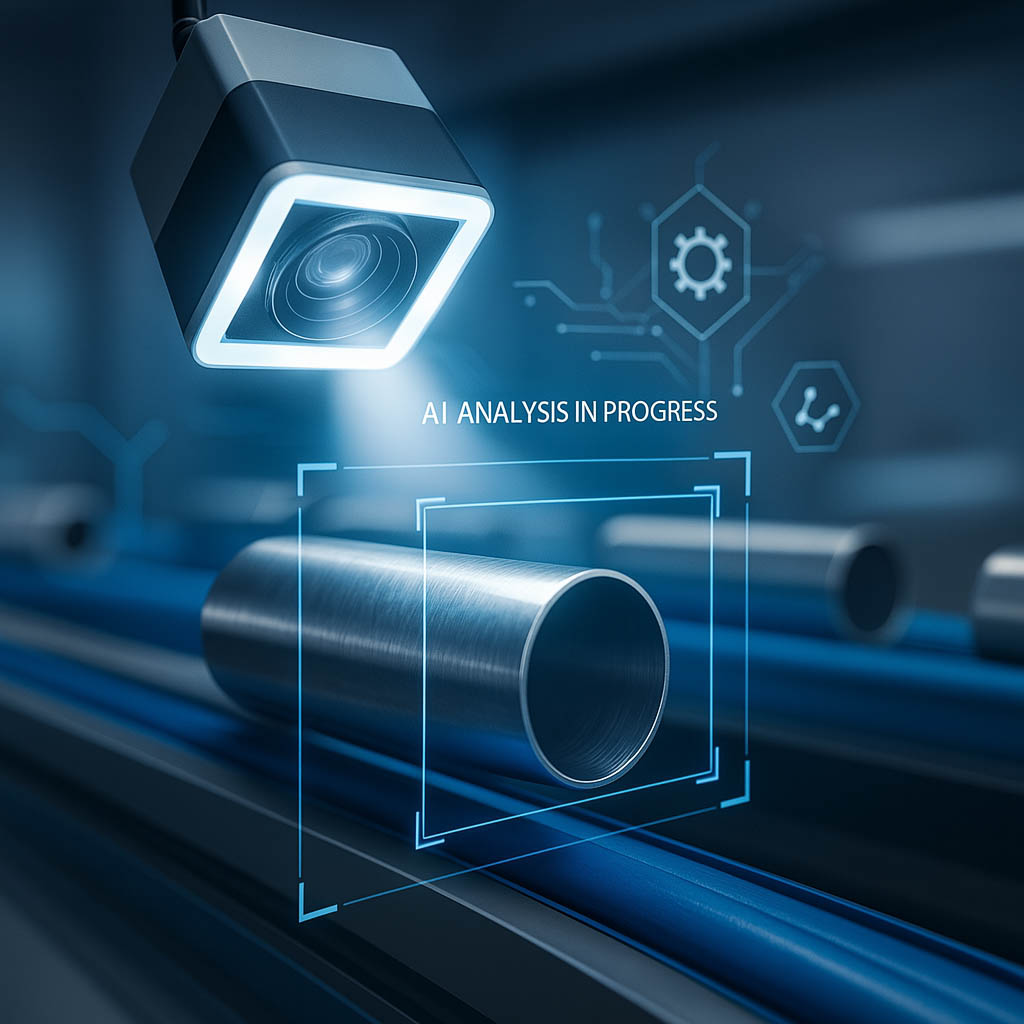

Machine Vision in Tube Quality Control

360° machine vision enables full, contactless inspection of each tube passing through the production line. With high-resolution cameras and AI algorithms, even the smallest defects are detected in real-time, enabling:

- Waste reduction

- Complete traceability

- Compliance with strict quality standards

- Prevention of future issues in final applications

As an automated system, it ensures continuous, objective, and faster inspection than manual processes.

Competitive Advantages for Companies

Implementing an advanced tube quality control system not only enhances product quality but also offers business benefits:

- Improved brand image by delivering flawless products

- Reduced returns and complaints

- Higher customer trust in demanding sectors like automotive, construction, or pharma

- Long-term cost optimization

Recommendation: AIS REV 360 Cables

For companies manufacturing or handling cylindrical tubes or cables, the AIS REV 360 Cables system from AIS Vision Systems is a robust and efficient solution. It offers full 360° inspection of moving tubes or cables, detecting imperfections with precision in real-time.

- Compatible with various diameters and materials

- Fully customizable to production line needs

- AI-powered software for classification and alarms

- Easy integration into industrial environments

Want to learn more about AIS REV 360 Cables? Contact us for a personalized demo.