Success story: Improving the quality and accuracy of label verification with the V275 for OPERON

07 - 06 - 2023

In the competitive healthcare sector, quality and precision are key factors to ensure regulatory compliance and meet customer demands. That’s why AIS Vision Systems, a leader in inspection solutions, is proud to present an exciting success story in collaboration with OPERON, a renowned company dedicated to the design, development, manufacturing, and distribution of in vitro diagnostic medical devices. In this article, we will explore how AIS Vision Systems helped OPERON implement a state-of-the-art label verification solution, overcoming challenges and achieving outstanding results.

OPERON, based in Zaragoza, Spain, is a company with extensive experience in the healthcare sector. With a focus on manufacturing in vitro diagnostic medical devices, OPERON has established its reputation by delivering high-quality products worldwide. OPERON serves multinational clients in the pharmaceutical sector in key markets such as Europe and the United States.

Previous Situation and Challenge:

OPERON faced a significant challenge: they needed a solution that would allow them to print and verify 100% of the labels and printed tapes used in their products. This involved detecting defects, verifying 1D and 2D codes, and inspecting print quality according to ISO 15415/15416 standards. The absence of a comprehensive inspection system had led OPERON to rely on manual sample-based checks, which were insufficient to meet the high-quality standards demanded by their customers.

Implemented Solution:

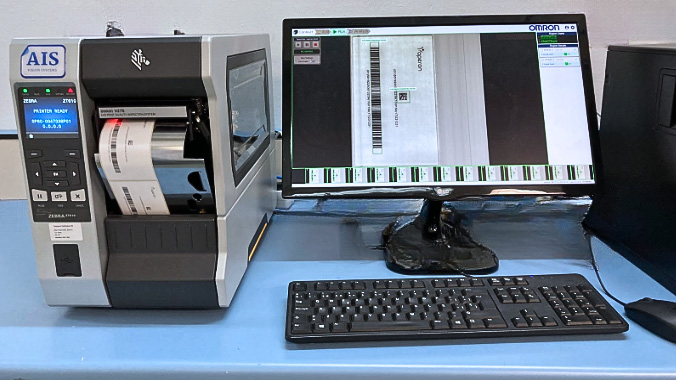

OPERON turned to AIS Vision Systems, experts in inspection solutions, to address this challenge. We supplied and implemented a state-of-the-art verification system, the V275, to complement the existing LVS7510 system. The LVS V275, integrated into the Zebra ZT610 printer with 600 DPI, allowed for higher resolution and compliance with ISO standards for printed 1D and 2D codes. This expanded solution enabled OPERON to print and verify smaller labels, starting from 20 mm wide, which was not possible with the previous system.

Advantages and Benefits for OPERON:

The implementation of AIS Vision Systems’ label verification solution provided OPERON with a range of significant advantages and benefits.

- Significantly improved print quality of 1D and 2D ISO/GS1 symbols, ensuring greater readability and accuracy.

- Ability to print and verify smaller labels (starting from 20 mm wide), allowing for greater flexibility in label designs and formats.

- Compliance with important regulations such as FDA’s UDI and EU’s MDR, as well as FDA’s DSCSA and EU’s Falsified Medicines Directive.

- Substantial reduction in rejected products and distributor refunds, improving profitability, avoiding financial losses, and enhancing customer trust.

- Increased efficiency in the label inspection and verification process, saving time and resources.

- Ongoing technical support from AIS Vision Systems, providing assistance for inquiries, training, or any issues that may arise.

Successful Implementation and Satisfaction:

AIS Vision Systems played a crucial role in the successful implementation of this solution. They not only supplied the necessary equipment but also provided installation, configuration, training, and technical support services. The collaboration between AIS Vision Systems and OPERON began in September 2021, and the project was completed in October 2021. Throughout the entire process, AIS Vision Systems demonstrated their commitment to excellence and their ability to overcome any challenges that arose.

OPERON would wholeheartedly recommend AIS Vision Systems to other companies seeking high-quality label verification solutions. The experience with AIS Vision Systems has been exceptional, with constant support and responsiveness to all inquiries and challenges that arose during the project. AIS Vision Systems’ willingness to collaborate and develop new projects, along with improvements in the user interface and ease of configuration, make them the ideal partner for any company looking to enhance quality and precision in label verification.

In summary, the implementation of AIS Vision Systems’ label verification solution allowed OPERON to meet the high-quality standards demanded by their customers in the healthcare sector. The ability to inspect 100% of the labels and printed tapes, coupled with significant improvements in print quality, has positioned OPERON as a leader in their industry.